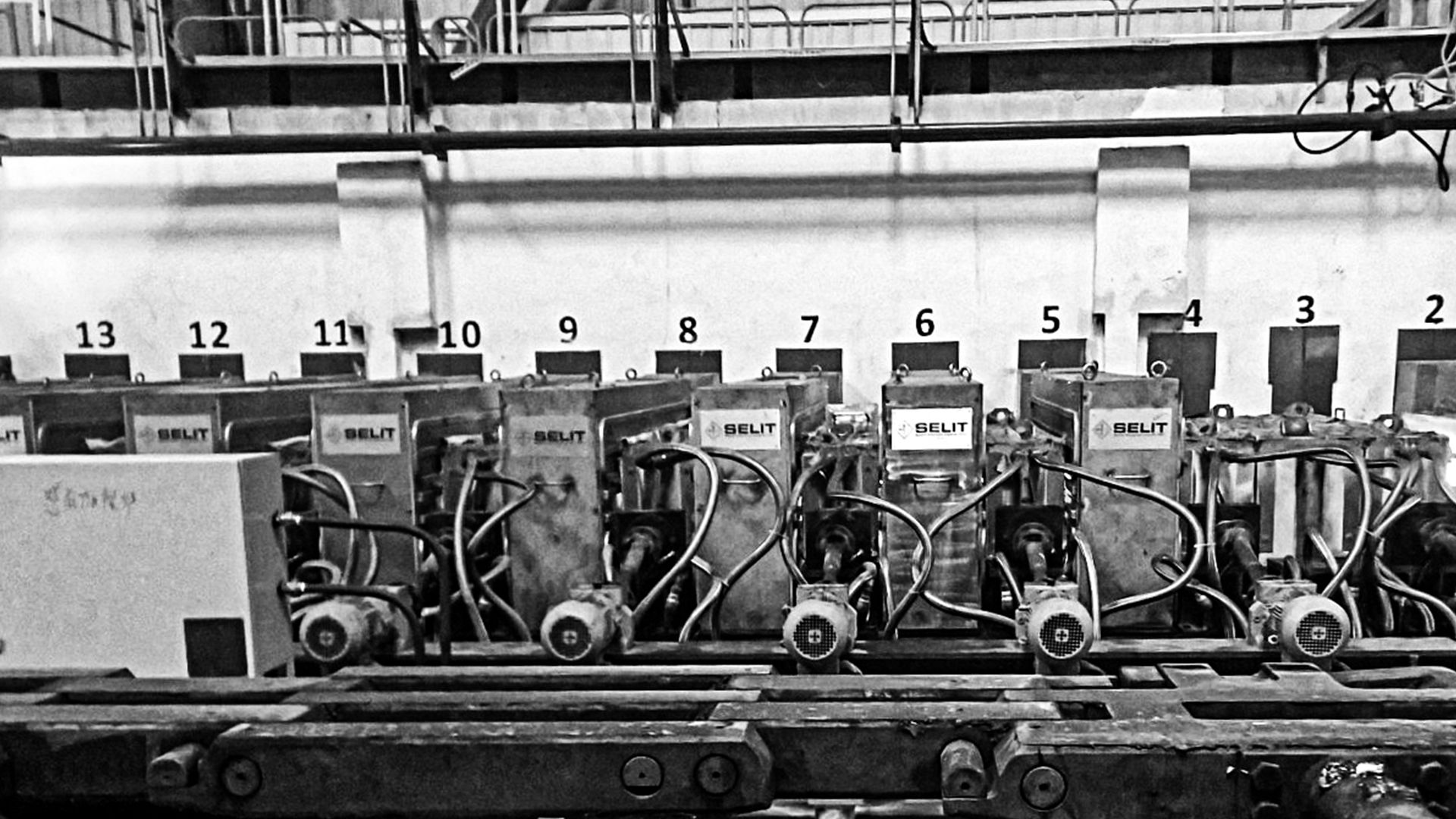

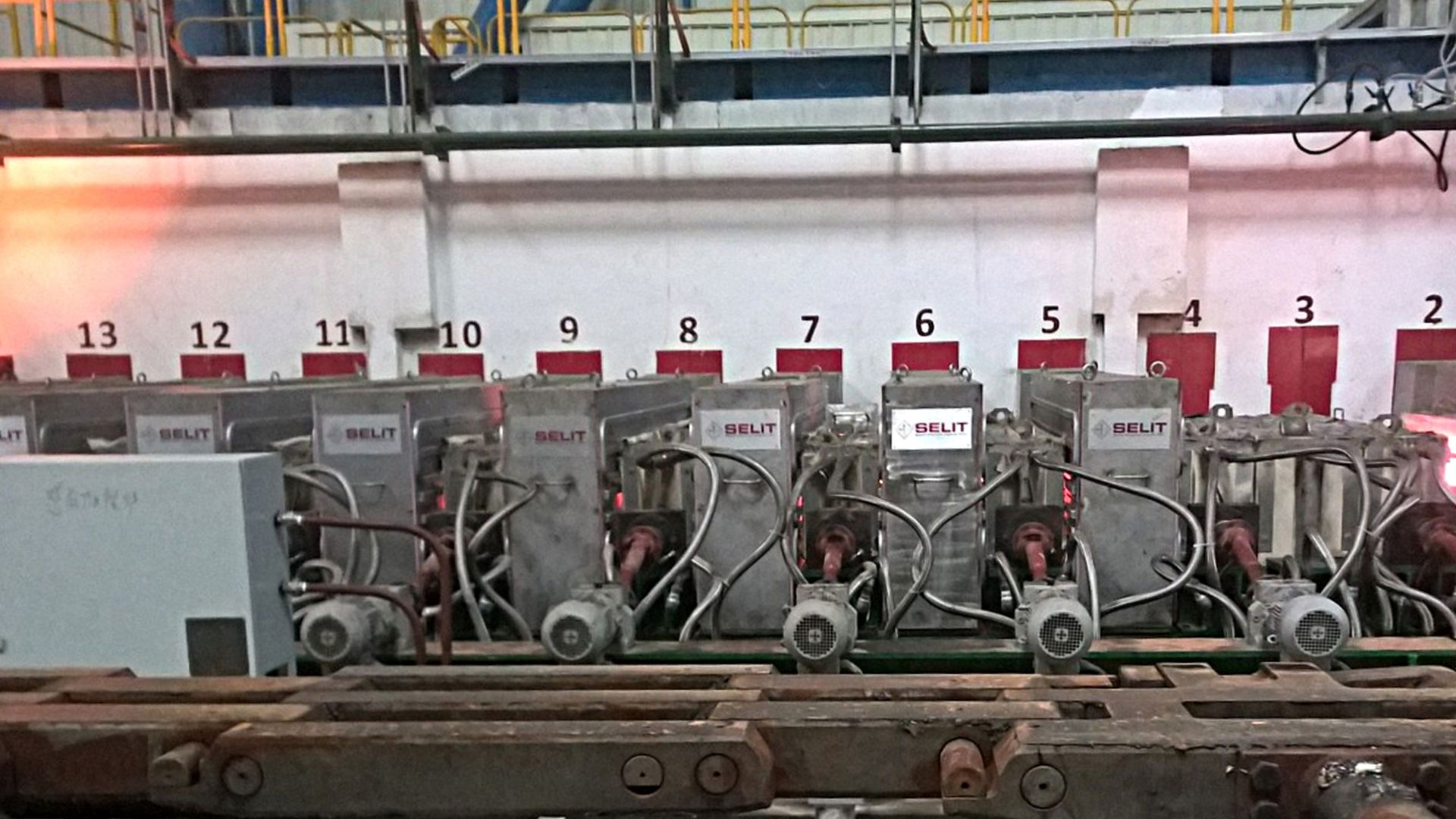

induction furnaces for hot rolling mills

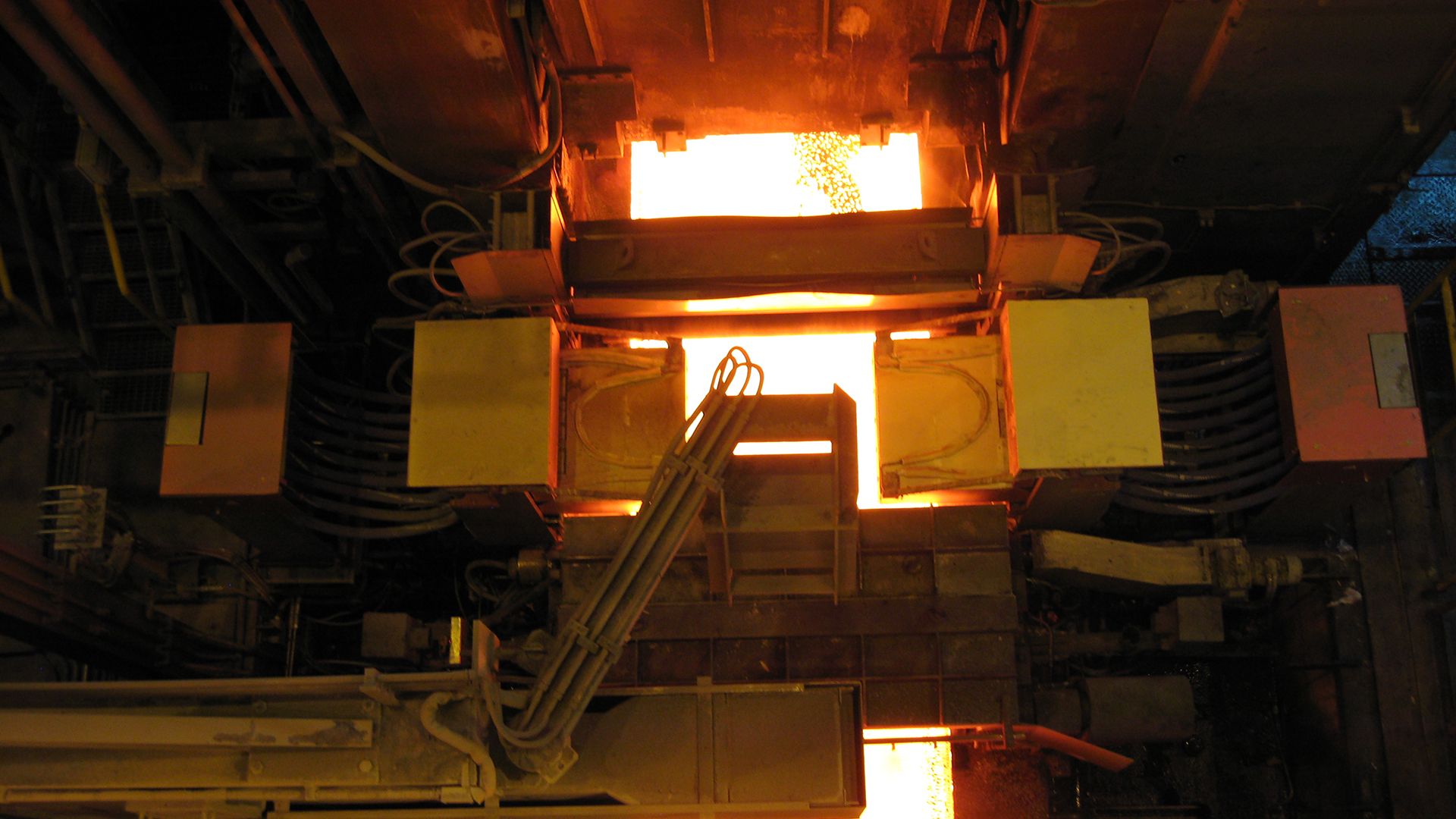

At the beginning of the 2000s, SELIT collaborated with ARVEDI steel mills in the development of continuous casting technology in flat laminates, called ARVEDI ESP, establishing itself as the first world manufacturer to have created a 36.000kW – 10 kHz induction temperature recovery system able to raise and equalize the temperature of slabs during mill rolling.

Since then, SELIT has designed and built numerous induction heating systems for slabs up to 2000mm wide and from 100mm to 9mm thick. SELIT always guarantees the maximum power of heating, even when there is a change in slab thickness, making it unique in the world.

Thanks to the SELIT’s system, it was possible to create the production line obtaining an overall energy saving of 50%.